EJECTOR

- Minimal risk of failure with no moving parts, virtually maintenance-free

- Long-term operation without concerns about vibration, wear, or leaks

- Possible to install directly in piping

- Suitable for confined spaces and limited installation environments

- Operates with only an energy source, requiring no electricity or lubrication

- No parts requiring periodic replacement

- Long-term operation possible with simple inspections only

- When configured in parallel, maintenance possible without shutting down the operation

- Vacuum distillation, evaporative concentration, degassing, gas suction, mixing, transfer, etc.

- Capable of handling diverse fluids, including steam, gases, liquids, and mixtures

- Superior cost-effectiveness compared to large mechanical vacuum pumps

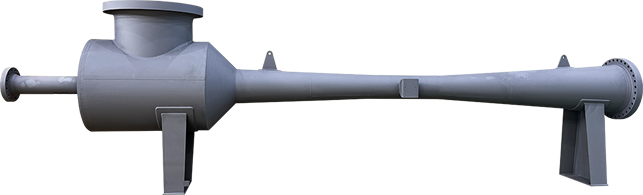

A typical ejector consists of three parts. The motive steam expands in the nozzle to the desired vacuum level. This steam is discharged from the nozzle at a high velocity of 1,000 to 1,200 meters per second. As the steam passes through the suction chamber, it draws in suction gas and carries it to the diffuser. In the diffuser, the steam-suction gas mixture decelerates and increases in pressure to the desired discharge pressure. Steam jet ejectors are simple and highly versatile compressors. Primarily used to create and maintain a vacuum in process equipment or test chambers, they can be flexibly designed for various suction pressure conditions, including above atmospheric pressure, provided sufficient steam is available. Additionally, ejectors offer high design flexibility as they can be fabricated from virtually any machinable material. SAMWON ENGINEERING designs and manufactures products in compliance with various international standards and codes, including ASME, HEI, TEMA, and ASTM. Our products are widely used not only for processes such as crystallization, drying, cooling, and high-vacuum distillation of liquids and solids, but also for the processing of essential oils, food products, and various chemicals. Through continuous research and development, we have developed high-performance product lines and maintain our own performance testing facilities to further enhance product reliability and quality.