EJECTOR

About the

TANK MIXING EDUCTOR

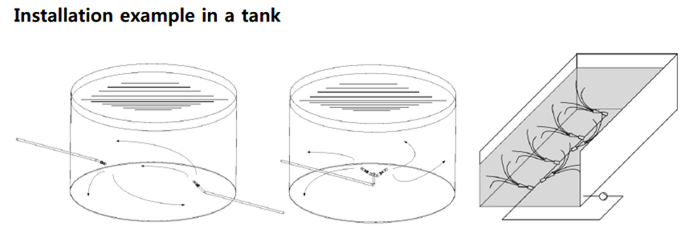

A tank mixing eductor circulates and mixes the contents inside a tank using high-pressure fluid flow without requiring a separate electric drive. By drawing in and discharging fluid using the Venturi effect, it achieves efficient liquid mixing, sediment prevention, and uniform concentration.

Advantage

Unpowered Mixing System Operating Without Electricity

- Mixing possible with a pressurized fluid alone

- Safe use even in explosion-proof zones or sites where electricity use is restricted

Robust Circulation and Uniform Mixing

- High-velocity jet injection creates strong circulation flow throughout the tank with no dead zones

- Uniform mixing possible for liquid raw materials, slurries, and solids

Simple Installation & Space Efficiency

- Unlike agitators, operates by simply connecting piping without installing separate equipment

- Minimizes facility interference by not occupying interior tank space

Applicable to Various Industries

- Possible to handle viscous fluids, corrosive fluids, and liquids containing solids

How it works

Eductors are used to agitate liquids, dissolve powdered solids into liquids, and effectively mix two or more liquids. These devices can be utilized as an alternative to conventional mechanical agitators. The operating principle is as follows: Liquid is drawn from the tank through a centrifugal pump and supplied to the eductor. Inside the motive nozzle, the liquid's pressure energy is converted to kinetic energy, forming a high-velocity flow at the nozzle outlet that draws in surrounding liquid. The drawn fluid is uniformly mixed with the motive fluid in the diffuser and discharged, with mixing performance further enhanced by the drag force generated during this process.

Use Cases

Chemical Industry

Uniform mixing of chemicals in reactors

Food/Beverage Industry

Mixing raw materials such as syrups, concentrates, and flavors

Water Treatment/Environmental Facilities

Mixing tanks for coagulants, acids/bases, and polymers

Refining/Petrochemical

Crude oil and additive mixing in storage tanks

Wastewater/Slurry Treatment

Mixing waste liquids containing solids and preventing re-flotation

Cleaning/CIP Equipment

Circulating and mixing cleaning solutions and tank washing

Technial Data