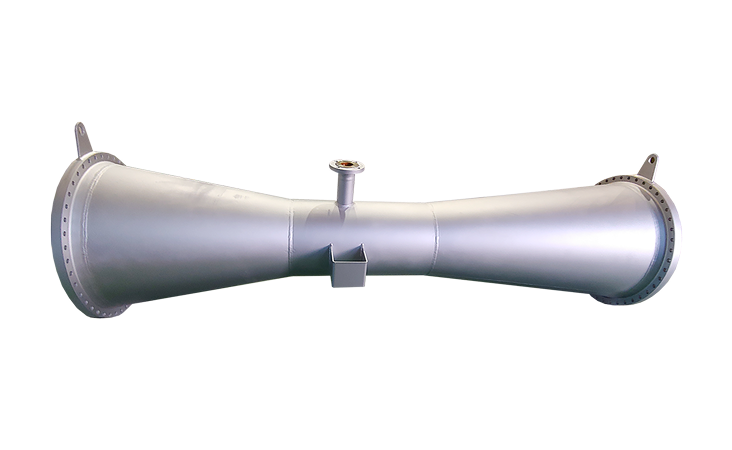

DESUPERHEATER

All desuperheaters operate on the same fundamental principle. Condensate or process water is injected into the high-temperature, superheated steam line, where direct contact with the steam causes the water to evaporate and lower the steam temperature. The injected water absorbs heat from the steam as it evaporates, reducing the steam temperature, and the outlet steam temperature is precisely controlled by the amount of water evaporated. It is advisable to use injection water at a temperature as close as possible to the steam temperature. This effectively absorbs the latent heat needed to reduce steam temperature, ensuring complete evaporation of water within the steam and preventing water droplets from forming on the pipe walls. As a result, desuperheaters maintain steam quality, maximize heat transfer efficiency, and help protect process equipment.