EJECTOR

- Optimized design of ejector configuration, materials, and components tailored to customer process conditions (vacuum level, flow rate, operating pressure, etc.)

- Multi-stage vacuum system design enables diverse applications

- Extremely low failure rate due to a structure with no moving parts

- Condensers, piping, and other components can achieve long-term maintenance-free operation depending on design

- Lower initial installation cost compared to mechanical vacuum pumps

- No power consumption during operation, reduced operating costs

- Material selection capable of withstanding high-temperature and corrosive environments

- Easy monitoring of operating conditions when automatic valves and instrumentation are included

- Used throughout vacuum-based processes, including refining, degassing, evaporation, distillation, and solvent recovery

- Applied across diverse industries, including chemical, pharmaceutical, refining, water treatment, food, textile, and semiconductor

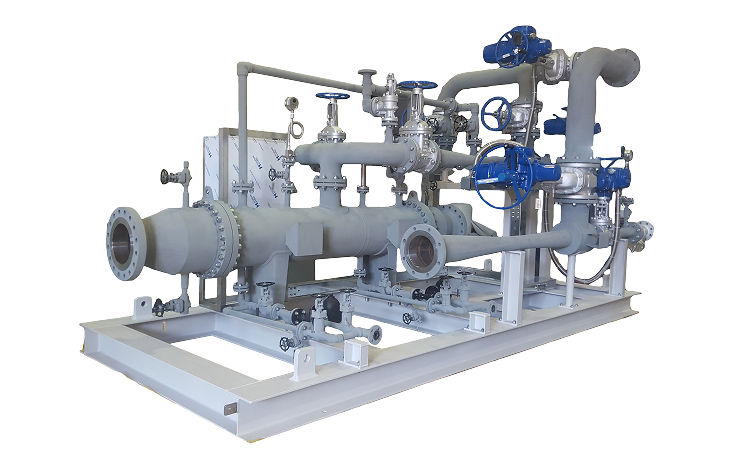

Since a single ejector has limitations in achievable compression ratio, multi-stage ejector systems consisting of two or more stages are used when higher compression ratios are required. Ejectors are fixed-flow devices whose capacity and performance are determined by the operating pressure. Multi-stage ejector systems achieve high vacuum by connecting multiple ejector stages in series. The first stage draws in fluid at the lowest pressure, and the second and third stages progressively increase pressure. The final stage discharges the compressed fluid at exhaust pressure or atmospheric conditions. Inter-condensers are installed between each ejector stage to condense steam, reducing the amount of gas entering the next stage and improving system efficiency. Additionally, an after-condenser condenses the remaining steam after the final stage to complete the system.