EJECTOR

About the

THEMAL VAPOR

RECOMPRESSOR(TVR)

RECOMPRESSOR(TVR)

A TVR is an energy-saving device that uses high-pressure steam to draw in and recompress low-pressure vapor (or waste vapor), converting it back into high-temperature, high-pressure steam that can be reused in processes. TVR reduces the amount of waste discharged to the atmosphere, thereby achieving environmental improvements and operating cost reductions.

Advantage

Energy Savings

- Discarded low-temperature steam can be reused as a process heat source

- Improved thermal efficiency in evaporators and concentrators (fuel cost reduction)

Environmentally Friendly Operation

- Reduced CO₂ emissions through waste steam utilization

- Supports greenhouse gas reduction and eco-friendly facility certification

Easy Installation and Operation

- Simple integration into existing evaporators and steam networks

- Possible for stable unmanned operation

Applicable to Various Industries

- Applicable across diverse industries, including food, pharmaceutical, chemical, refining, paper, and seawater desalination

- Stable operation even in high-vacuum, high-temperature, and corrosive environments

Excellent Return on Investment

- Low initial investment with immediate energy-saving effects

- Speedy recovery of initial investment costs in plants with high steam costs

How it works

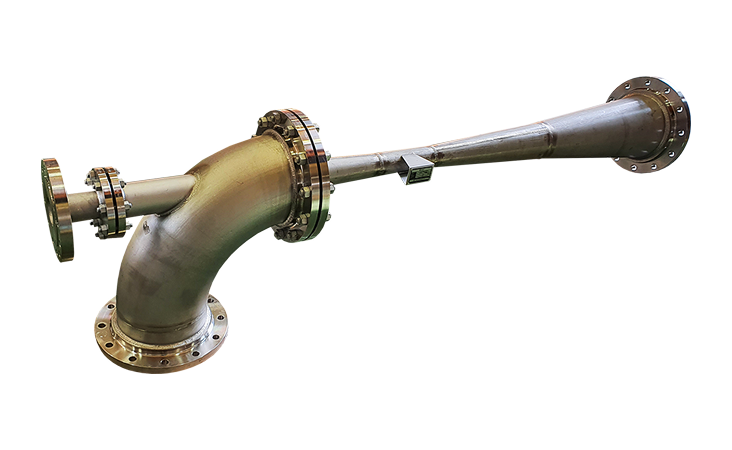

A thermal vapor recompressor (TVR) is an ejector that recycles low-pressure waste vapor using high-pressure steam. The TVR ejects high-pressure motive steam at high velocity through a nozzle, inducing low-pressure vapor. At this point, the two vapor streams are uniformly mixed in the suction chamber, and the low-pressure vapor is accelerated through the energy of the motive steam. Suction vapor is induced by momentum exchange between the motive fluid and suction fluid, with uniform mixing occurring at the narrowest part of the diffuser. Finally, the velocity energy is reconverted to pressure energy in the diffuser's expansion section. As a result, it is discharged at a pressure between high and low pressure.

Use Cases

Food/Beverage

Energy savings in evaporators during the concentration of milk, fruit juice, and syrups

Pharmaceutical/Bio

Used in low-temperature concentration processes for drug extracts, amino acids, and fermentation liquids

Chemical Industry

Utilized in evaporators for solution concentration, wastewater concentration, and recycling

Seawater Desalination

Used in processes that evaporate seawater for desalination

Refining/Petrochemical

Low-pressure steam recovery, vapor recycling from the bottom of distillation columns

Power Plants/Boilers

Recompressing low-pressure exhaust steam for resupply to boilers

Technial Data