EJECTOR

About the

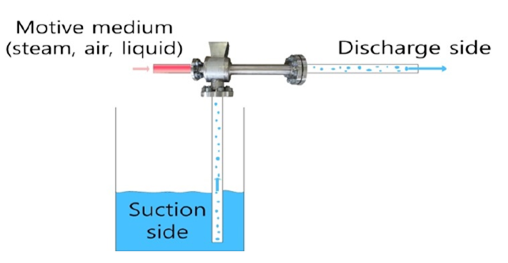

SUMP EJECTOR

A sump ejector is a device that pumps liquid accumulated in a sump and discharges it elsewhere. The motive fluid can be freely selected from steam, air, liquid, and other options.

Advantage

Usable in High-Temperature and Corrosive Environments

- Heat-resistant and corrosion-resistant materials applicable

- Feasible to be used for high-temperature steam, waste liquids, and chemical processing

Capable of Transferring Fluids Containing Sludge, Sediment, and Foreign Matter

- Possible to discharge liquids containing sludge, fibers, and solids without clogging

- Suitable for drainage wells, sludge tanks, tank bottom cleaning, and similar applications

Easy Installation and Utilization of Confined Spaces

- Easily installable in underground wells and beneath compact equipment

Operates Without Electricity

- Operates with compressed air or steam only, without electric motors or rotating parts

- Feasible to be used in areas where electrical installation is difficult

How it works

The high-pressure injection action of the motive fluid creates a vacuum inside the ejector, drawing in suction fluid and discharging both fluids under pressure. As the suction fluid is pumped, the sump level drops to the selected level gauge point. No further pumping action occurs until the sump refills to the operating level.

Use Cases

Chemical/Refining Plants

Removal of sludge and sediment from reactor or storage tank bottoms

Power Plants

Boiler drains, condensate discharge

Marine/Offshore Plants

Removal of bilge water from ship bottoms or tanks

Pharmaceutical/Food Plants

Floor water around sanitary facilities, drainage well cleaning

Water/Wastewater/Environmental Facilities

Sludge wells and contaminated water tank drains at wastewater treatment plants

Technial Data